overturn! UV insulation coating instead of blue film? Power battery, the new trend

01

At the beginning of 2023, BMW officially announced that its first cell spraying production line was officially put into use, replacing the "blue film" with a new acrylic system UV insulation coating scheme.

Figure source | network

PET blue film is a kind of PET single-face tape made of pressure sensitive adhesive on the back of the substrate (PSA). This kind of products are mostly dark blue, so it is called "blue film".

According to German media reports, BMW's first battery spraying production line began mass production at its Leipzig plant in early 2023. In addition to the existing two battery module production lines and the new battery cell spraying lines, a battery module production line, four battery cell spraying lines and two assembly lines for the production of high-voltage batteries will be added by April 2024.

This scheme is a combination of BMW and Liangkwei Ze (lankwitzer) coating, using UV curing coating as a new solution for leakage protection between cells, China has entrusted Ningde Times (CATL) for OEM production.

Not only BMW, some well-known car manufacturers have also tried to use UV insulation coating technology in power batteries, including Volkswagen, Volvo and so on.

In the near future, will the mainstream cell insulation scheme —— PET "blue film" be eliminated by UV insulation coating?

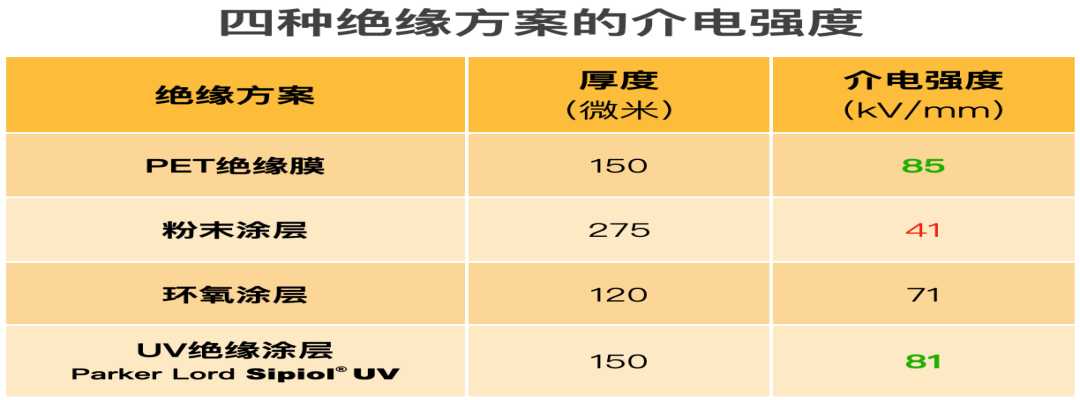

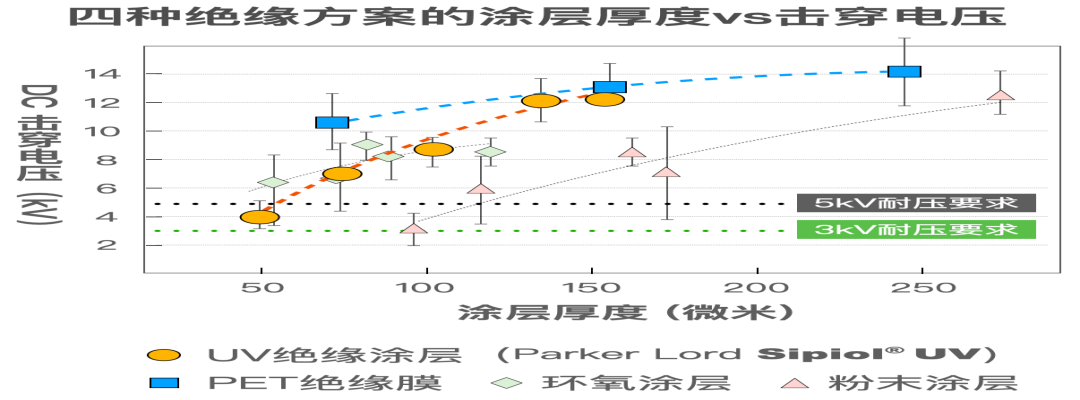

The material company Parker Lord published a white paper on Insulation Protection Technology for Battery System Components, targeting polyethylene terephthalate (PET) films, powder coatings, solvent-based coatings and UV-cured coatings

Four materials were tested for analysis.

Figure source | Parker Lord company of the battery system components of insulation protection technology evaluation white paper

The test subjects are four insulating materials:

PET thin films used commercially for electrical insulation applications

A heat-cured powder coating designed for electrical applications with a good edge-covered LORD®JMC-700K, a heat-cured solvent-based epoxy coating Sipiol®UV, a UV-cured and 100% solid, acrylate-based paint

Figure source | Parker Lord company of the battery system components of insulation protection technology evaluation white paper

▋ According to Parker Lord research, "blue film" has excellent insulation protection and can withstand different environmental conditions. The equipment investment cost and material cost of blue film are low, but the automation difficulty is high, suitable for less batch production, high cost performance, and the qualified rate is controllable. However, its adhesion is generally low, so it may be limited to applications without high structural adhesion, which will directly affect the safety performance of power batteries.

▋ Powder coating is suitable for many fields, powder coating has excellent performance. However, it has low dielectric strength at low film thickness and requires large ovens and high temperatures for thermal curing.

▋ Solvent-based coatings have excellent adhesion, dielectric strength, and thermal conductivity. However, this type requires a long application process and high-temperature curing.

▋ UV-curing coatings have excellent insulation protection, adhesion and the fastest production efficiency. However, its thermal conductivity is relatively low compared to powder coatings and solvent-based coatings.

In general, the spraying and curing of UV curing coating only takes a few seconds, requiring less time, manpower and energy, which can make up for the shortcomings of "blue film", and is one of the most economical products applied in the high-throughput manufacturing environment.

02

As the core component of new energy vehicles, the performance and safety of power battery are very important for the overall performance of electric vehicles.

According to the New Energy Vehicle Industry Development Plan (2021-2035) issued by The General Office of the State Council in 2020, it clearly requires "to accelerate the research and development and industrialization of solid-state power battery technology".

On the market, tesla's 4680 battery, byd's blade battery, CTB, Ningde era kirin battery, etc., the common characteristics of these new battery, are done a lot of innovation on the structure and material, greater energy density, better safety, longer life, these characteristics of all kinds of battery packaging, isolated materials are put forward higher requirements.